AI-Powered Predictive Maintenance Solutions are Cutting Downtime in Utilities and Telecom

Reading Time:

7 Minutes

What’s the real price of an outage? For AT&T, a 12-hour nationwide network blackout in February 2024 proved catastrophic, blocking 92 million voice calls and leaving 125 million devices disconnected, which led to long-term damage to customer trust and brand reputation. In the energy sector, US businesses lose $150 billion annually to power outages, with a single transformer failure running up emergency bills in the millions.

Whether it is a failing grid in Texas, a fiber backbone in Germany, or a regional blackout in Sydney, the story is consistent: downtime is no longer just an operational inconvenience. It is a boardroom issue that directly impacts revenue, reputation, and resilience.

In this blog, we’ll explore shared challenges across regions and how AI-powered predictive maintenance, integrated with Operational Support Systems (OSS), Business Support Systems (BSS), and geospatial intelligence (GIS), helps overcome them.

Why downtime is a shared global headache

Despite differences in regulation, market maturity, and geography, telcos and utilities in North America, Europe, and ANZ are facing the same challenges.

1. Aging infrastructure under pressure: In the US, much of the electric grid dates back to the 1960s and 70s, with transformers averaging 40-60 years in service. European utilities are working to integrate renewables into networks designed decades ago, while ANZ operators are pushing equipment built for lighter loads far beyond its original limits.

The risk stretches from generation plants and Central Offices (COs) to utility poles, underground conduits, and Fiber Distribution Hubs (FDHs) or Remote Terminal (RT) cabinets, which too often fail without warning.

2. Rising costs and shrinking margins: 5G networks consume 2–3 times more power than 4G, while smart grids and IoT-enabled infrastructure multiply the number of failure points. At the same time, McKinsey reports that telecom capital intensity keeps climbing (globally around 23%) even as revenue growth remains flat.

Whether it is a US provider competing with hyperscalers or a European incumbent managing copper networks and heavy regulation, the financial squeeze is universal.

3. Inefficiencies across dispersed networks: 40% of organizations have suffered a major outage from human error between 2022 and 2025, with 85% of those traced back to ignored or flawed procedures.

In 2025, error-related outages rose another 10% compared to the year before. Staff shortages compound the issue, leaving crews reacting to breakdowns instead of preventing them. Moreover, with assets scattered across cities, rural areas, and remote terrains, operators often lack visibility into what is happening on the ground.

4. Regulatory and environmental pressures: North American operators must navigate complex rules while also investing heavily in climate resilience. This is critical if you consider that US suffered $53 billion in weather-related infrastructure damage in 2024, nearly double the cost of 2023!

European leaders are adapting to the EU AI Act, alongside new sustainability mandates that are reshaping business models. ANZ executives face vast geographic dispersion and intensifying climate risks, from floods in New Zealand to wildfires in Australia, all of which threaten dispersed field assets.

How AI-powered predictive maintenance integrated with OSS, BSS, and GIS helps fight downtime

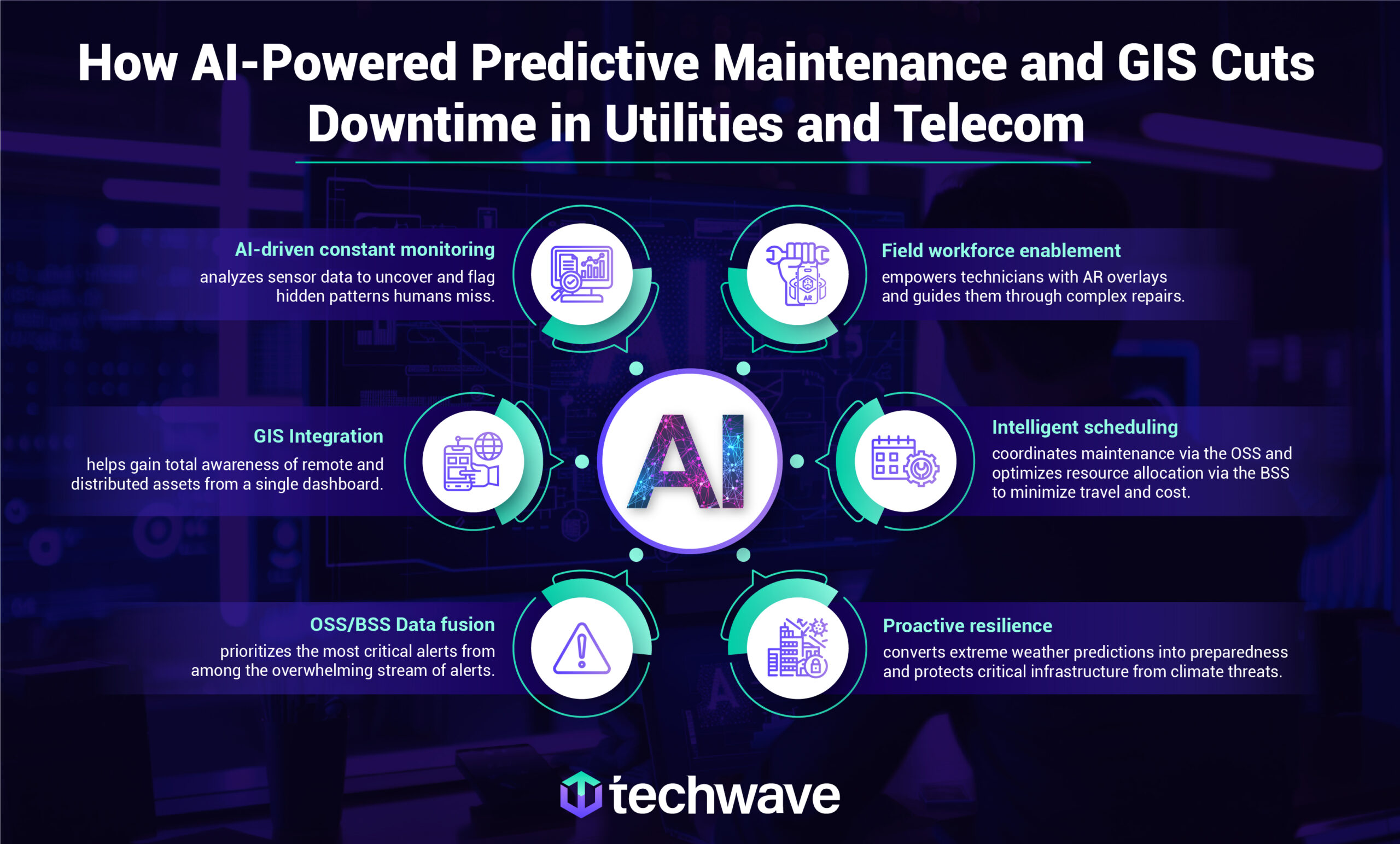

Predictive maintenance powered by Artificial Intelligence (AI) and Geographic Information System (GIS) gives operators the ability to move from firefighting to foresight. By integrating these capabilities directly into core Operational Support Systems (OSS) and Business Support Systems (BSS), companies can now anticipate failures and keep Outside Plant (OSP) networks and grids running smoothly. Here’s how AI makes that possible.

1. Detecting early warnings from every piece of equipment

Every piece of equipment, whether it is a fiber amplifier along a telecom line, a roadside cabinet, or a transformer in an electrical grid, constantly emits subtle signals about its condition. These signals can appear insignificant at first glance, like tiny temperature fluctuations, slight vibrations, or minor deviations in electric current.

AI-powered predictive maintenance has the unique ability to detect these patterns and convert them into actionable alerts. The technology continuously analyzes streams of sensor data in real time, recognizing early signs of wear, stress, or impending failure that humans often miss.

For instance, a modern Remote Fiber Monitoring System (RFMS) that uses AI/ML to analyze backscattered light signals (collected using Optical Time Domain Reflectometer (OTDR) technology) and pinpoint the exact location and nature of a potential optical fiber fault, such as a bend or a break, long before it causes a service outage.

Consider this scenario: a construction project begins near a major fiber route. An AI-integrated RFMS detects a new, gradual increase in signal loss at a specific coordinate, the classic signature of a cable being slowly stressed or bent by digging equipment. Instead of waiting for a backhoe to sever the line and take a data center offline, the system alerts network operators instantly. They can map the exact location using GIS, dispatch a technician, and resolve the issue during off-peak hours, preventing a catastrophic outage and saving millions in potential downtime costs. It’s incredible, given the barely evident symptom that led to such a massive save!

Over time, these predictive insights allow telecom operators to prioritize the most critical maintenance tasks, reducing emergency interventions and extending the life of network assets. By translating granular sensor data into clear, early warnings, AI-powered predictive maintenance transforms what might otherwise be an unpredictable risk into a controlled, manageable process.

2. Managing assets outside main network facilities

Managing distributed assets outside central network buildings presents a significant challenge. Poles, underground ducts, roadside cabinets, and remote substations are constantly exposed to environmental stress, accidental damage, and natural aging. Manually inspecting these assets is costly and labor-intensive, often resulting in reactive maintenance rather than proactive interventions.

When AI-powered predictive maintenance is integrated with GIS, operators gain a detailed understanding of asset health across vast areas. Geospatial and environmental data layers, such as topography, soil conductivity, historical floodplain models, and Right-of-Way (ROW) data, can be combined with real-time sensor inputs to pinpoint locations most at risk.

For instance, a cluster of telecom cabinets in a low-lying, flood-prone area showing rising humidity levels before heavy rains can trigger preemptive maintenance. In the US, utility companies can reinforce poles or replace aging transformers in anticipation of storm season, while telecom teams can prepare underground ducts in high-risk zones.

By combining AI analytics with spatial intelligence, operators move from reacting to outages toward preventing them, making downtime rare and expensive incidents even rarer.

3. Filtering alerts and recommending actions

Complex Outside Plant (OSP) networks generate massive amounts of alerts every hour, which can overwhelm technicians. Without prioritization, it becomes impossible to distinguish between minor events and critical failures. This is where integration with core operational systems becomes critical.

AI doesn’t work in a vacuum; it feeds into the Operational Support System (OSS), the platform for monitoring and controlling the network, and the Business Support System (BSS), which handles customers, orders, and billing. This integration allows AI to rank alerts not just by technical urgency, but by potential business impact. It can calculate the revenue at risk from a failing asset or prioritize a fault affecting a Service Level Agreement (SLA) for a major enterprise client over a less critical one.

More practically, if a fiber node experiences strain, AI can reroute data traffic automatically through the OSS, mitigating customer impact, and recommend maintenance during periods of low usage. Overloaded transformers in the grid can trigger automatic load balancing while creating a schedule for preventive replacement.

Telecom operators can identify the busiest towers showing early signs of overheating, while utility operators can focus on substations critical to hospitals or emergency services. This predictive approach reduces reactive firefighting, ensures resources are allocated efficiently, and minimizes downtime. By turning raw data into clear priorities, AI ensures that operators act on the right problems at the right time.

4. Supporting the field workforce

Field crews are facing a workforce transformation. As experienced technicians retire, new hires who require training are left to face growing operational demands. Here, AI-powered predictive maintenance acts as a digital co-pilot, guiding inexperienced crews step-by-step and providing context-specific instructions.

When a warning arises from a GIS-plotted asset on the network map, AI analyzes the situation in its spatial context, suggesting likely causes, recommending the appropriate tools, and specifying the required spare parts. In case of a fiber cut, RFMS leverages GIS to pinpoint the exact location, helping field crews respond quickly and reducing the Estimated Time to Repair (ETR). This intelligence is pushed directly to mobile workforce applications, which are often part of a broader OSS ecosystem.

These mobile applications tap into this live GIS data to provide crews with navigational guidance and step-by-step instructions specific to that location. On-site, Augmented Reality (AR) application uses the smartphone’s camera to overlay the AI’s diagnostic data, such as the exact failing component, precisely onto the real-world equipment, visually bridging the digital GIS record with the physical asset.

This allows utility crews to navigate directly to and replace a failing switch before it triggers a cascading fault and telecom teams to precisely swap out a malfunctioning cabinet module without trial and error.

This integration of AI with GIS and OSS ensures fewer mistakes, faster interventions, and minimized downtime. By acting as an intelligent assistant, AI empowers less experienced staff to operate at the efficiency level of veterans, transforming field operations across both telecom and utilities.

5. Planning maintenance to reduce costs

Beyond frustrating customers, unplanned downtime also imposes significant financial costs. Emergency repairs, expedited shipping for parts, and penalties for service disruption can accumulate rapidly.

AI-powered predictive maintenance, fueled by constant monitoring of GIS-integrated network data, enables operators to plan ahead intelligently, feeding optimized work orders directly into the OSS for scheduling and the BSS for cost analysis and resource allocation. This balances operational needs with cost efficiency.

For example, telecom operators predicting multiple cell site failures can pre-order Line Replaceable Units (LRUs)/modular parts and schedule cluster-based visits, reducing labor and travel expenses. Utilities can use AI to predict vegetation encroachment on power lines, enabling targeted trimming cycles before outages occur.

Similarly, they can replace transformers during low-demand periods, avoiding costly service interruptions. By prioritizing interventions based on risk and predicted failure, AI allows operators to consolidate work, optimize resource allocation, and maintain budget stability.

Predictive scheduling also reduces redundant maintenance activities, allowing teams to focus on high-impact tasks. Over time, these strategies decrease operational costs, improve efficiency, and protect both revenue streams and customer satisfaction.

6. Preparing for extreme weather

Extreme weather events pose a major threat to both telecom and utility networks. Heat waves, floods, heavy rainfall, bushfires, and storms can damage equipment and disrupt services.

AI-powered predictive maintenance, when combined with weather forecasting and environmental data, and analyzed within a geographic information system, converts broad uncertainty into spatially-precise, actionable insights. GIS maps the predicted storm path, flood zone, or fire perimeter directly onto the network model, instantly highlighting assets in harm’s way.

Before a storm, AI can flag these vulnerable cell towers for reinforcement and suggest rerouting data traffic to prevent outages. During heat waves, transformer loads can be redistributed to maintain safe operating temperatures.

Similarly, ANZ telecom operators can protect underground duct networks in flood-prone areas, deploy fire-resistant measures to critical infrastructure in high-risk bushfire zones, and utility companies can preemptively replace aging poles likely to fail under high wind or fire conditions.

By combining predictive asset health with environmental intelligence, operators move from reacting after the fact to building proactive resilience, reducing downtime, and ensuring service continuity even under challenging conditions.

Why Techwave is the partner that makes predictive maintenance real

Turning predictive maintenance from concept into reality takes much more than clever algorithms. It demands a partner who can blend customized app development, AI, GIS, IoT, cloud systems, OSS/BSS integration, and field operations into a system that works seamlessly across telecom and utility networks. That’s where Techwave comes in.

We help operators move from reacting to outages to preventing them altogether by designing AI-powered systems that continuously monitor asset health, anticipate risks, and feed actionable insights directly into field operations and core business systems.

Whether it’s extending the life of transformers, using an RFMS to spot fiber vulnerabilities before they disrupt service, or mapping OSP assets with geospatial intelligence, Techwave makes downtime far less likely and resilience far more achievable.

If you want to see how an integrated AI-based predictive maintenance solution can reduce outages, boost reliability, and bring peace of mind to your operations, get in touch with us. And to see how this approach has delivered measurable reductions in outages and maintenance costs for our clients, explore our detailed.